Wires used on boats

In the olden days there was only one way to put an eye on the end of a wire – you had to make an eyesplice. To make it strong and to keep the wire from making too sharp of a bend, which would cause it to break, you could use a thimble.

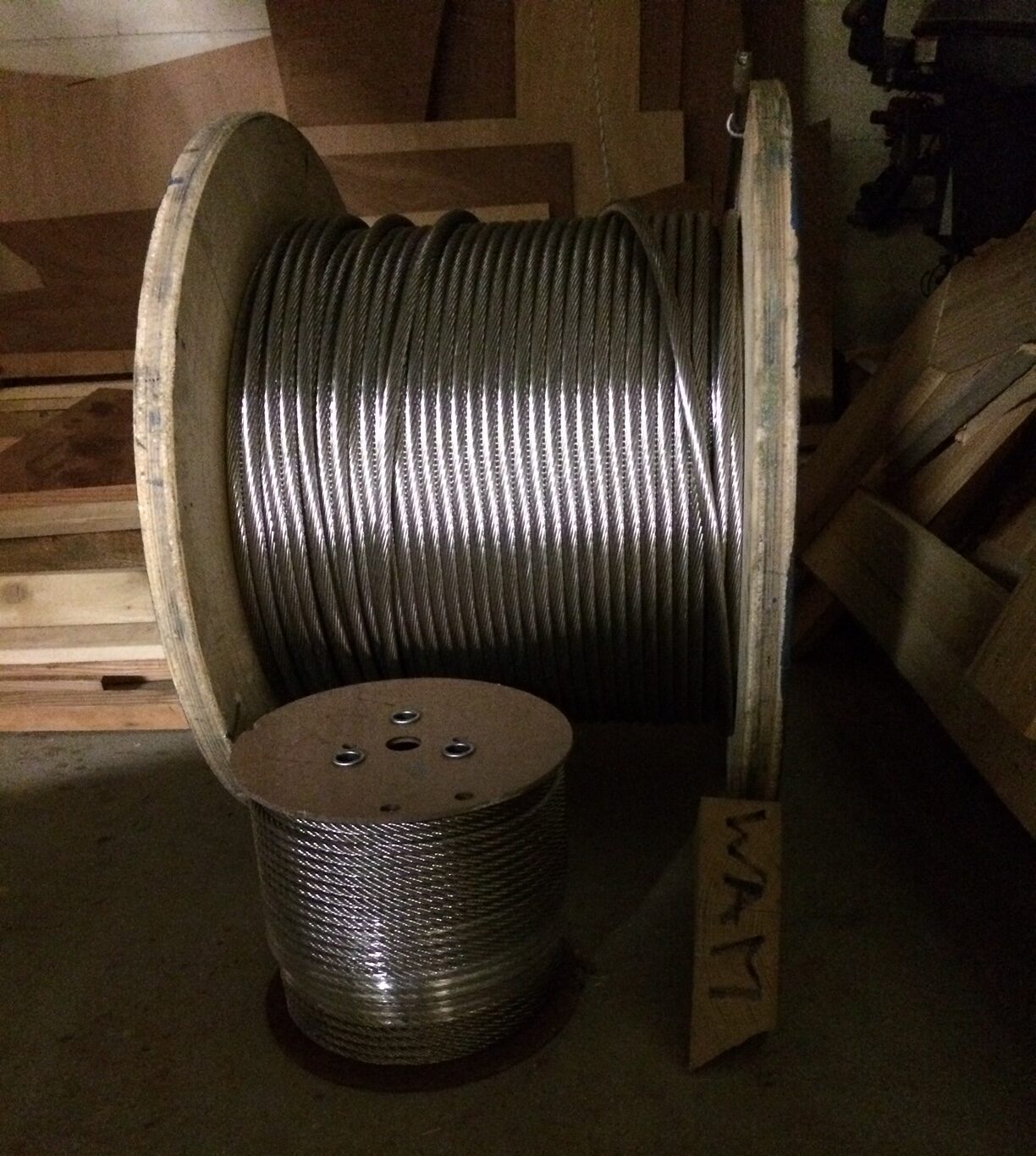

There are many different types of wire. On boats the most common ones are 7×19, 7×7 and 1×19. 7×19 means that there are 7 strands that are made up of 19 single wires each. This is the most flexible type generally used only for halyards.

7×7 consists of 7 strands with 7 single wires each. This is the type often used on traditional sailboat rigs. It is quite bendy and fairly easy to splice. The result is smooth, as the strands can be untwisted a little so they lay snugly next to each other.

1×19 wire is widely used for the standing rigging of production sailboats. The cross section shows 1 straight wire in the middle with 6 more wires twisted around this center wire. 12 more wires are then twisted in the oposite direction around this core. All together 19 wires. It is possible to splice 1×19 wire but the splice will never be as smooth as with 7×7.

For equal diameter 1×19 wire is strongest. This means that for equal strength you can choose a thinner 1×19 wire compared to 7×7. But 1×19 is not quite so easy to splice – not until you get the hang of it. As a matter of fact, many rigging shops think it is not possible and will guide you to terminal fittings instead.

We will not get into the details of splicing work here. There is enough literature out there to explain how it is done. I can highly recomend the book «The Complete Rigger’s apprentice» by Brion Toss.

Why does it make sense?

The main reason for splicing instead of using other type of terminals lies in the superior suppleness of spliced wire terminals. On traditional boats the rig is usually not tensioned quite as much as on newer boats. When sailing upwind in a breeze these rigs go through full load changes with every tack. The wires on the windward side stretch a little, while the ones to leeward shorten due to the elasticyty of the material.

If the terminal does not allow for this adjustment the wire right at the exit of the terminal succumbs to fatigue over time. That is the reason why shrouds often break right at the exit of swaged on terminals. Of course water that infiltrates and causes pit corosion does not help neither…